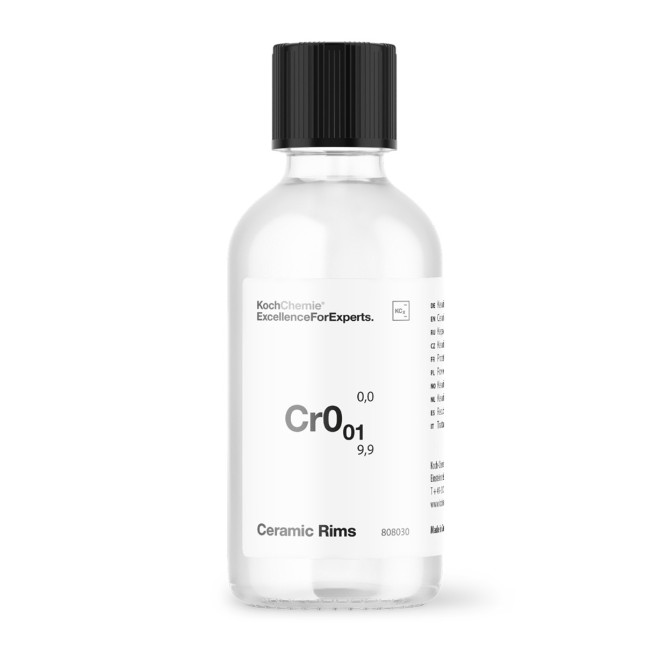

Ceramic Coating for painted rims

Ceramic Rims Cr0.01 is a ceramic coating that provides painted rims with long-lasting protection. The protective layer bonds permanently to the surface through a chemical reaction, creating a very good beading behaviour (lotus effect). Thanks to the easy-to-clean properties, the treated surface can also be cleaned gently and easily by hand washing. The protective layer remains intact even after the use of acidic and alkaline cleaners. The hardened ceramic sealant protects the rim's paintwork for much longer against environmental influences such as salt and brake dust build-up, making cleaning and maintenance easier. The service life is up to 12 months, depending on the maintenance. Ceramic Rims Cr0.01 can be double-coated. Please follow the washing and care instructions.

1. Clean the wheel thoroughly before the coating process (e.g. with Magic Wheel Cleaner). For coarse dirt, such as brake dust, use suitable accessories (e.g. Detail Wheel Brush). 2. Before coating all surfaces , wipe with Panel Preparation Spray or Silicone & Wax Remover using the Polish & Sealing Towel . Wipe dry with another clean Polish & Sealing Towel. This completely removes surfactants, drying aids etc. to avoid adhesion problems with the Ceramic Rims Cr0.01. Caution: To avoid possible matting, the Silicon & Wax Remover should be diluted with water, preferably distilled water, in a ratio of 1:4. 3. After this step, do not touch the paint with your palms/fingers (risk of adhesion problems, use gloves). The surface is now perfectly prepared for Ceramic Rims Cr0.01. 4. Use the application pen for application and coat the entire surface with Ceramic Rims Cr0.01. Spread the ceramic evenly over the surface. After application, a thin, closed liquid film must be visible. Allow the product to flash off and then level and remove excess residue with a Coating Towel. *Optimal conditions: Temperature from 15°C / 59°F to 25°C / 77°F, humidity from 40% - 50%. If the temperature/humidity is higher, the flash-off time must be shorter. If the temperature/humidity is lower, the reaction cannot take place properly. Consumption depending on rim size and design approx. 5-7 ml per rim Before use, please read the hazard warnings on the container or outer carton and take appropriate protective measures. Ceramic Rims Cr0.01 reacts with humidity. This can cause crystals to form on the rim when the bottle is open. If these crystals get onto the application pen, the surface to be coated will be scratched. Therefore, the crystals must be wiped off with a cloth before the product is dripped onto the application pen. For double coats, a drying time of approx. 30 minutes should be observed after the first coat, depending on the temperature and humidity. The coating is only weatherproof after at least 24 hours. First vehicle wash should be after nine days at the earliest, as the coating is not fully cured until then. At low outside temperatures (below 15°C / 59°F), the curing time is extended. Nevertheless, soiling should be carefully removed as quickly as possible during the first nine days. The application of Spray Sealant S0.02 or Hand Wax W0.01 is recommended after 24 hours to protect the not yet fully cured ceramic coating. Cleaning agents with pH values below 3 or above 12 should be avoided. An opened bottle has a maximum shelf life of 6 months. Check the bottle for crystallization before use. Hand washing is recommended to preserve the ceramic surface for as long as possible. Use Green Star (dilution 1:10) for alkaline cleaning. Use Gentle Snow Foam for neutral washes. To remove mineral soiling, deep cleaning with Magic Wheel Cleaner or Reactivation Shampoo is recommended. Professional aftercare maintains the properties of the ceramic sealant. Hydro Foam Sealant S0.03 (dilution 1:50 - 1:200) is therefore recommended as a wet sealant, Spray Sealant S0.02 or Hand Wax W0.01 as a topper after cleaning the rims. Please refer to the product information for exact processing.